Wet Dust Suppression: Difference between revisions

No edit summary |

|||

| (2 intermediate revisions by the same user not shown) | |||

| Line 10: | Line 10: | ||

<math>K_t = SP\left ( \frac{T}{RH} \right )\left ( \frac{P}{\mu\times1.68} \right )</math> | <math>K_t = SP\left ( \frac{T}{RH} \right )\left ( \frac{P}{\mu\times1.68} \right )</math> | ||

SP is the wind speed in miles per hour, T is air temperature in °F, RH is relative humidity (%), P is the air density in pounds (lbs) per cubic feet, and μ is the air viscosity in lbs per | SP is the wind speed in miles per hour, T is air temperature in °F, RH is relative humidity (%), P is the air density in pounds (lbs) per cubic feet, and μ is the [https://www.grc.nasa.gov/www/BGH/viscosity.html air viscosity] in lbs per square feet hours. The constant of 1.68 is the value of P divided by μ at standard conditions of 70°F, RH of 60%, and P of 2116 lbs per square feet. The term T/RH reflects the tendency of the coal piles to emit particles when temperatures are high and/or RH is low.<ref name=":02">Air Pollution Control Board, Hampton Roads Region, [./File:Coal_Study-January_1987_21391318.pdf Control of Fugitive Emissions from Open Coal Storage in Newport News], Virginia, January 1987.</ref> | ||

The [[Virginia Air Pollution Control Board|APCD]] developed the equation for ''K<sub>t</sub>'' to guide and optimize wet dust suppression with sprayers in [[Southeast Newport News]]. Their 1987 study found a strong relationship between the [[Particulate matter and coal dust|daily summed ''K<sub>t</sub>'' (Σ''K<sub>t</sub>'') and the amount of particles]] measured in the air. Because [[Particulate matter and coal dust|coal dust emissions]] are reduced on cloudy, rainy, foggy, and humid days, the [[Virginia Air Pollution Control Board|APCD]] developed a weight (''F<sub>c</sub>'') to be multiplied by ''K<sub>t</sub>'' to include the effects of rain and fog on coal dust emissions. ''F<sub>c</sub>'' is a value between 0 and 1, with heavy fog (visibility less than 4 miles) or rain (more than 0.3 inches) giving a value of ''F<sub>c</sub>'' equal to zero, meaning ''K<sub>t</sub>'' x ''F<sub>c</sub>'' = 0''.'' | The [[Virginia Air Pollution Control Board|APCD]] developed the equation for ''K<sub>t</sub>'' to guide and optimize wet dust suppression with sprayers in [[Southeast Newport News]]. Their 1987 study found a strong relationship between the [[Particulate matter and coal dust|daily summed ''K<sub>t</sub>'' (Σ''K<sub>t</sub>'') and the amount of particles]] measured in the air. Because [[Particulate matter and coal dust|coal dust emissions]] are reduced on cloudy, rainy, foggy, and humid days, the [[Virginia Air Pollution Control Board|APCD]] developed a weight (''F<sub>c</sub>'') to be multiplied by ''K<sub>t</sub>'' to include the effects of rain and fog on coal dust emissions. ''F<sub>c</sub>'' is a value between 0 and 1, with heavy fog (visibility less than 4 miles) or rain (more than 0.3 inches) giving a value of ''F<sub>c</sub>'' equal to zero, meaning ''K<sub>t</sub>'' x ''F<sub>c</sub>'' = 0''.'' | ||

| Line 32: | Line 32: | ||

=== Water quality === | === Water quality === | ||

[[File:Dominion Terminal Water Application.jpg|alt=Dominion Terminal Water Application|thumb|While the sprinklers are not on at the moment of the photograph, large amounts of standing water are visible at the [[Companies: railroads, terminals, and coal|Dominion Terminal]] in Southeast Newport News.]]What happens to the large volumes of water sprayed on to the coal piles? At the [[Coal Terminals in the Port of Virginia|Dominion Terminal]], coal pile runoff and storm water drain into treatment ponds where coal settles out before being discharged into the lower James River. | |||

There were also notes of many spills of oil and fuel from the equipment and vehicles that also migrated into the discharged water. The DEQ also notes that this region of water is impaired for aquatic life such as fish and submerged vegetation. This can also degrade the odor and appearance of the shoreline thus impacting water recreation. | |||

There are many impervious surfaces within the terminals. If these surfaces are not kept clean, heavy rainfall can cause untreated runoff from these surfaces to enter waterways or nearby neighborhoods. | |||

== Types of Surfactants == | == Types of Surfactants == | ||

Latest revision as of 22:00, 24 November 2025

Coal dust pollution in Southeast Newport News and Lambert's Point are primarily mitigated using wet suppression methods that consist of spraying water, or water with chemical additives, over coal storage piles, railcars, and/or transloading equipment with a system of sprinklers and water trucks. Water application is in theory adjusted based on terminal activity and ambient meteorological conditions. According to a representative from Norfolk Southern, most coal-carrying railcars are sprayed with chemicals when they leave the coal mines, minimizing the dust emissions en route to terminals.[1]

Wet Dust Suppression in Hampton Roads

History

1920s: Water suppression of coal dust emissions is mentioned in the record as early as the 1920s, when the Chesapeake and Ohio (C&O) Railroad Company installed a custom pipe system to spray water on coal-filled railcars where and when the cars were emptied through overturning.[3]

1950s: Following pressure by the Garden-Shores Civic League, the City of Newport News hired a chemical engineering firm to measure the amount of coal in airborne particles. This study found that at least in one location in Southeast Newport News 45% of airborne dust was un-combusted coal. In response, the Newport News City Council compelled C&O to install equipment to create a water fog over the coal piers to suppress dust and led Newport News City Council to pass an air pollution ordinance.[4]

1980s: Community activism and residents' complaints to Virginia Air Pollution Control Board (APCB) led the APCB to conduct additional research on the factors that influenced coal dust emissions and develop a wet suppression approach that was more effective. This research was published in the report: Control of Fugitive Emissions from Open Coal Storage in Newport News, Virginia. As part of this study, researchers developed a mathematical formula for the effective wind forces (Kt) on the terminals' coal piles using readily available meteorological measurements.

SP is the wind speed in miles per hour, T is air temperature in °F, RH is relative humidity (%), P is the air density in pounds (lbs) per cubic feet, and μ is the air viscosity in lbs per square feet hours. The constant of 1.68 is the value of P divided by μ at standard conditions of 70°F, RH of 60%, and P of 2116 lbs per square feet. The term T/RH reflects the tendency of the coal piles to emit particles when temperatures are high and/or RH is low.[5]

The APCD developed the equation for Kt to guide and optimize wet dust suppression with sprayers in Southeast Newport News. Their 1987 study found a strong relationship between the daily summed Kt (ΣKt) and the amount of particles measured in the air. Because coal dust emissions are reduced on cloudy, rainy, foggy, and humid days, the APCD developed a weight (Fc) to be multiplied by Kt to include the effects of rain and fog on coal dust emissions. Fc is a value between 0 and 1, with heavy fog (visibility less than 4 miles) or rain (more than 0.3 inches) giving a value of Fc equal to zero, meaning Kt x Fc = 0.

To develop a standardized water sprinkler cycle for both Southeast Newport News terminals, the APCB tested the only recognized wind speed value of 12 miles per hour at which dust may become significant, which was reported in a 1984 study from the U.S. Environmental Protection Agency (EPA) Office of Air, Noise and Radiation, and the Office of Air Quality Planning and Standards.[6] We note that we only found a related report from 1985. This value was used as a starting point to initiate a spray cycle, which would be repeated hourly as long as Kt remained above 12, with a one hour delay between cycles. It is not stated how long the sprinklers remained on per cycle. In a second experiment, if the hourly Kt reached or exceeded 28, hourly spray cycles would be employed as long as this condition existed. If Kt did not exceed 12 on a given day, the sprinklers were turned on at 11:00 am and 2:00 pm in a so-called assurance cycle. In the case approaching extreme weather, the National Weather Service was to provide both terminals with warning information, with the terminals initiating water spraying hourly until Kt fell below 12.

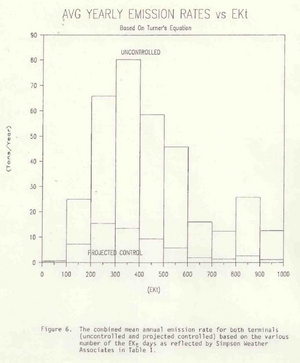

The difference between the uncontrolled concentration of particles based on ΣKt divided by the number of cycles performed, was used to determine the percent reduction in coal dust emissions per cycle (%R/C) for a cycle applying 24,000 gallons of water.

The dust emissions reduction attained (ATT) was then equal to the reduction in coal dust emissions per cycle (%R/C) multiplied by the number of cycles (C).

Today

Despite decades of dust control using water suppression, nearby residents continue to report that coal dust negatively impacts local air quality, outside and in their homes, leaves dust films on outdoor and indoor surfaces, harms quality of life, and requires residents and property owners to bear high air filtration costs.[7] That said, it is commonly held that coal dust pollution in Southeast Newport News was worse before the water suppression sprinkler system was upgraded in the 1980s. Residents describe seeing sprinklers that are frequently off and/or not turned on until winds are very fast.[8]

The Dominion Terminal now uses 79 sprinklers, turned on about four times per day or more depending on the weather, as well as a water truck dispatched to locations not covered by the sprinklers.[9] The Kinder Morgan Bulk Terminals use a system of 44 sprinklers to spray water that suppresses dust emissions from the piles and transloading equipment. In 2022, Kinder Morgan spokesperson Amy Baek claimed the Kinder Bulk Morgan Terminals used 20,000 gallons of water every hour to suppress dust emissions.[7] A record has not been found as to when the terminals trasitioned away from the spray cycles developed by the APCD in 1987.

Water suppression is argued to be effective at fairly low cost.[10] The terminals in Southeast Newport News and Lambert's Point have fought against other dust mitigation methods, not because they do not work, but because of their cost.[11][8] However, relative costs are a small fraction of the terminals' annual revenue.[12]

Water quality

What happens to the large volumes of water sprayed on to the coal piles? At the Dominion Terminal, coal pile runoff and storm water drain into treatment ponds where coal settles out before being discharged into the lower James River.

There were also notes of many spills of oil and fuel from the equipment and vehicles that also migrated into the discharged water. The DEQ also notes that this region of water is impaired for aquatic life such as fish and submerged vegetation. This can also degrade the odor and appearance of the shoreline thus impacting water recreation.

There are many impervious surfaces within the terminals. If these surfaces are not kept clean, heavy rainfall can cause untreated runoff from these surfaces to enter waterways or nearby neighborhoods.

Types of Surfactants

In general, dust suppressants should be durable, protective, easy (meaning they do not significantly impede transportation processes), cost-effective, and non-toxic. A variety of formulas are on the market, including oils, waste oils, oil emulsions, latex sealants, lignin derivatives, polyacrylamides and proprietary formations, each with their own drawbacks.

Currently, there is no documentation that can independently verify the projected PM control efficiencies for most of these options.[13]

- Plain or mist water sprays

- Commonly installed at conveyor transfer points, rotary dumpers, hoppers, and stockpiles.

- Rely on fine water droplets (typically 10–200 µm) to adhere to dust and settle it out of the air

- Mist cannons or Dry Fog systems

- Ultrafine droplets (<10 µm) form an airborne “blanket” that agglomerates dust in enclosed areas like hoppers.

- Surfactant‑enhanced sprays

- Addition of surfactants reduces water surface tension to improve adhesion to fine, hydrophobic coal dust. This method enhances capture efficiency and conserves water compared to plain sprays

- Foam suppression: Foam mixes water, air, and a foaming agent to create a lasting layer that traps dust at high‑impact zones (e.g., conveyor ends, crushers) with minimal moisture addition

- Products like Nbco DustBind, DustBind Plus, DustLock, HAUL‑EZE, and HAULAGE‑DC are polymer or salt-based additives applied via spray. They form a flexible crust over coal to prevent wind erosion and self-heating, especially during rail transport and stockpile storage

Concerns

Some of the chemicals are environmentally toxic and present potential problems if spray run-off and spillage is allowed to fall onto ground unprotected by a collection pad.

Additionally, measuring the efficiency of these solutions is very difficult, and is still a developing process.

Documents

- Han, F. et al. A review of water-based suppressants for coal dust suppression. September 24, 2024.

- Railroads of Port Adopt Coal Sprinkle: Growing demand for Sprinkled Coal Said to Be Made by Trans-Shippers, Daily Press, November 23, 1927

- Ohio Office of Air Pollution Control, Reasonably Available Control Measures for Fugitive Dust Sources (Part 1), September 1980

- Ohio Office of Air Pollution Control, Reasonably Available Control Measures for Fugitive Dust Sources (Part 2), September 1980

- Ohio Office of Air Pollution Control, Reasonably Available Control Measures for Fugitive Dust Sources (Part 3), September 1980

- Ohio Office of Air Pollution Control, Reasonably Available Control Measures for Fugitive Dust Sources (Part 4), September 1980

- City Planning Commission Meeting Minutes, City of Newport News, May 2, 2018

- Email Correspondence between Richard Posner of Dust Solutions, Inc. and Repair Lab Team Member, 2023

- Repair Lab, Coal Dust in Southeast Newport News is a Nuisance and There Are Solution (Corrected), August 2024

- Wituschek E. et al. Coal Dust Control: Recommended practices for loading, unloading and transporting coal by rail. Regional Report No. 86-17. April 1986.

References

- ↑ Lawlor, Newport News, Coal Terminals Looking Into Wind Fence, Daily Press, August 1, 2011.

- ↑ Murry, Coal Dust Causes Concern (Continued from Page C1), Daily Press, January 27, 1985.

- ↑ Railroads of Port Adopt Coal Sprinkle: Growing demand for Sprinkled Coal Said to Be Made by Trans-Shippers, Daily Press, November 23, 1927.

- ↑ C&O to Install Costly Equipment for Control of Air Pollution in NN, Daily Press, December 12, 1956.

- ↑ Air Pollution Control Board, Hampton Roads Region, [./File:Coal_Study-January_1987_21391318.pdf Control of Fugitive Emissions from Open Coal Storage in Newport News], Virginia, January 1987.

- ↑ APCB, Hampton Roads Region, Control of Fugitive Emissions from Open Coal Storage in Newport News, Virginia, January 1987.

- ↑ 7.0 7.1 Vogelsong, Virginia Will Begin Monitoring Air Pollution around Hampton Roads Coal Terminals: Residents of Newport News’ East End Say There’s Been Too Many Studies and Too Little Action, Virginia Mercury, April 19, 2022.

- ↑ 8.0 8.1 [./File:CPC_Minutes_5.2.18.pdf City Planning Commission Meeting Minutes], City of Newport News, May 2, 2018.

- ↑ Lawlor, Coal dust, piles an issue for southeast Newport News, Daily Press, July 16, 2011, Updated: August 18, 2019.

- ↑ Ohio Office of Air Pollution Control, Reasonably Available Control Measures for Fugitive Dust Sources (Part 2)], September 1980.

- ↑ [./File:Notes_on_email_correspondence_between_Richard_Posner_of_Dust_Solutions.pdf Email Correspondence with Richard Posner, President of Dust Solutions Inc.], 2023.

- ↑ Repair Lab, Coal Dust in Southeast Newport News Is a Nuisance and There Are Solutions (Corrected), August 2024.

- ↑ Han, F. et al. A review of water-based suppressants for coal dust suppression. September 24, 2024.